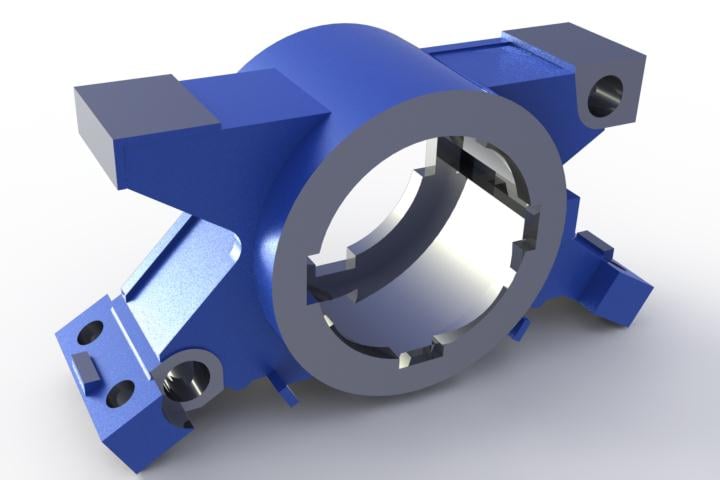

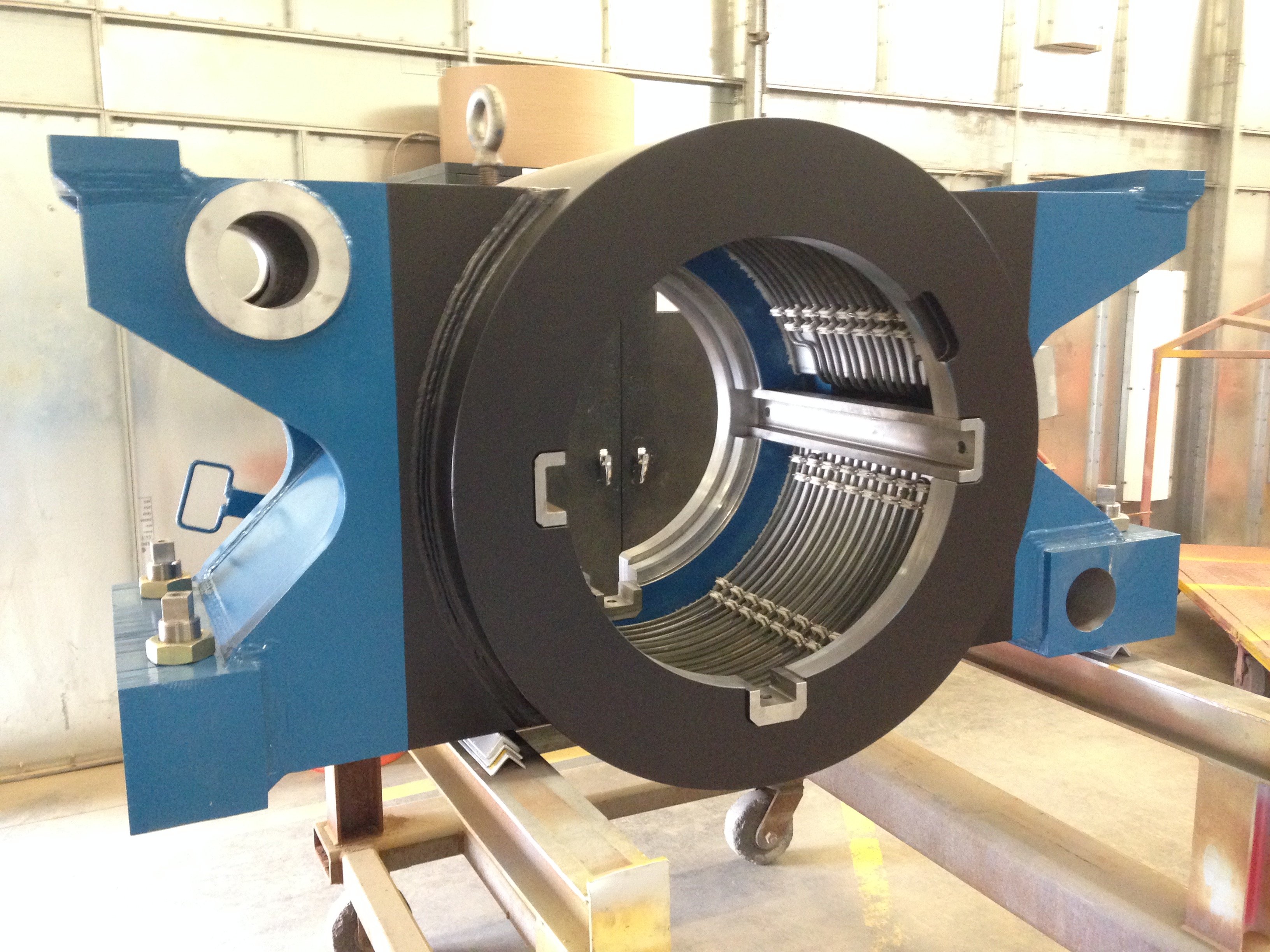

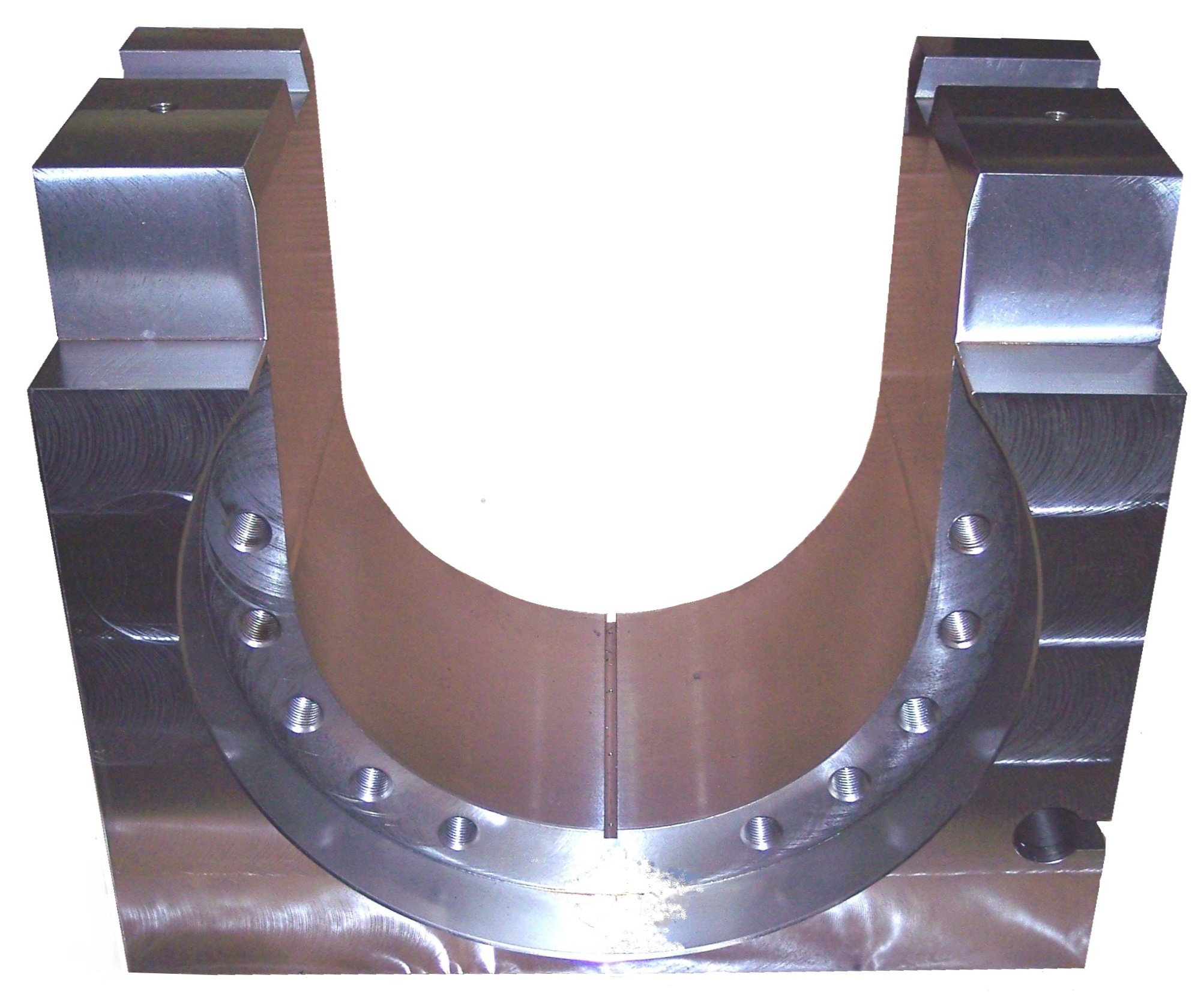

Container Housings

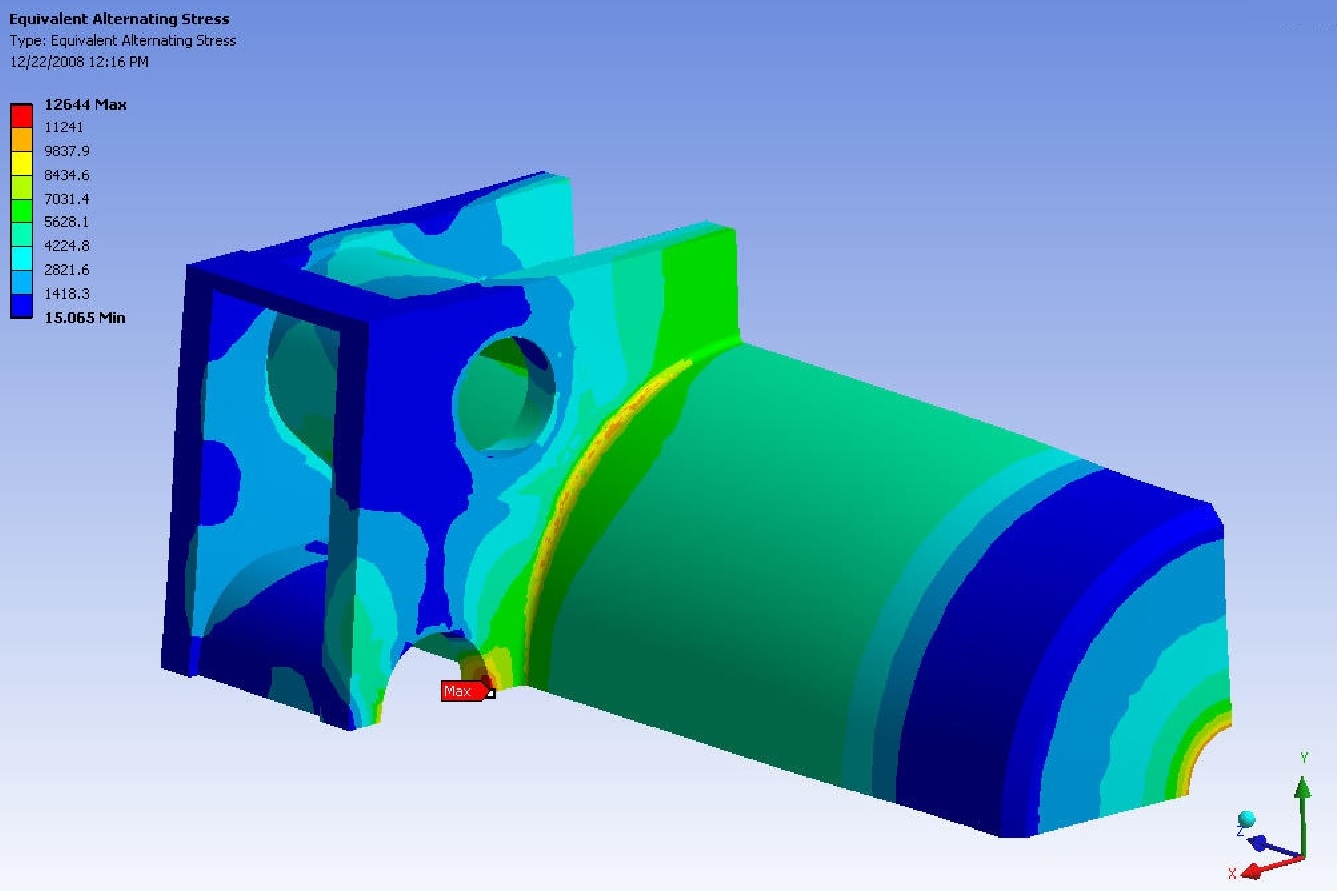

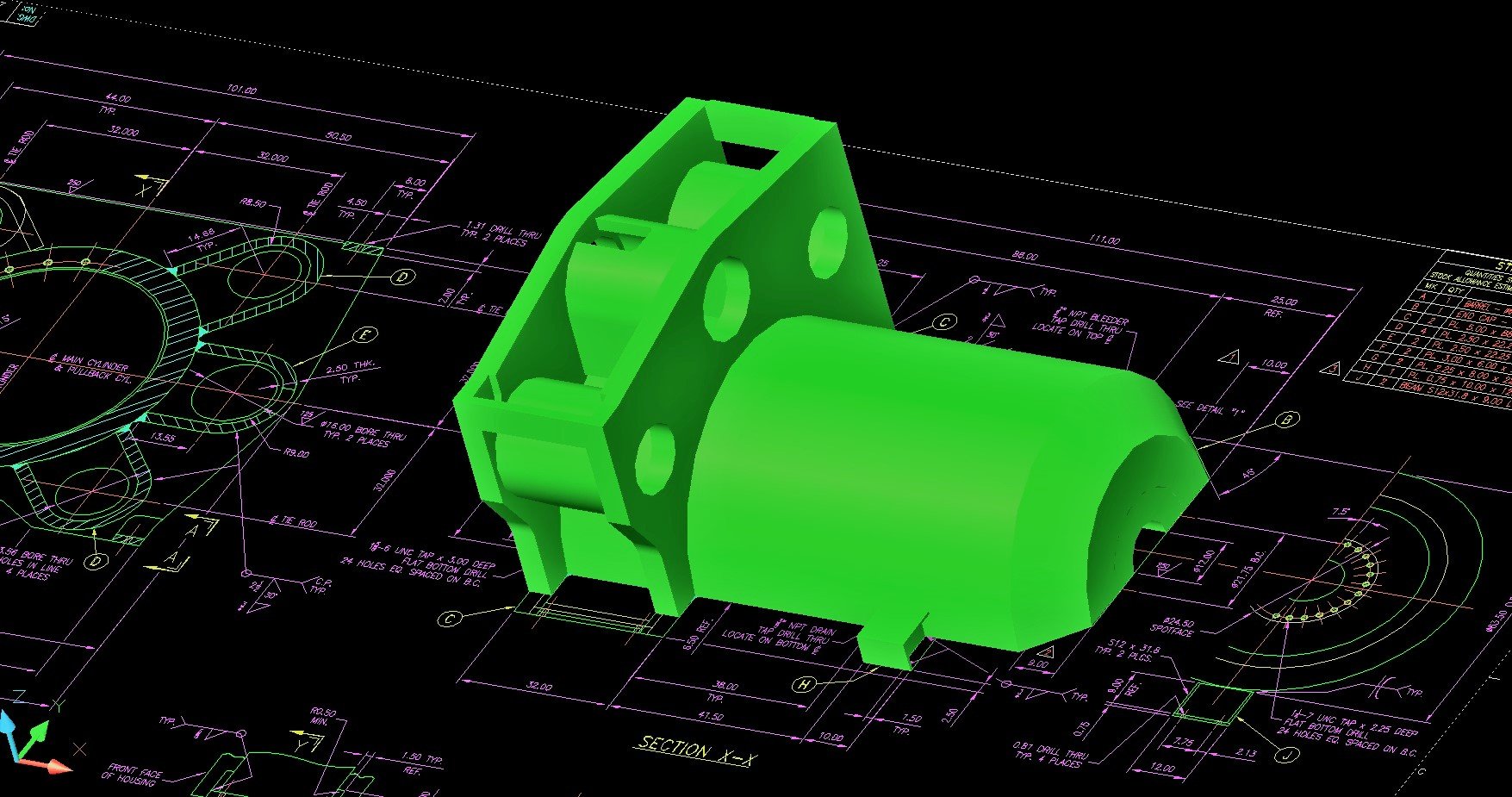

We engineer forged and fabricated container housings for strength, reduced fatigue, and press alignment. To further improve your press’s performance, we include a quick container release system and four-point X guiding.

Need a manufacturing partner you can lean on for design advice? BTS’s heavy-press division has 30+ years of continued experience developing solutions for a breadth of extrusion production components.. In fact, many presses currently in use in the industry were fundamentally based on our lead engineer’s design!

Having a supplier with experience you can trust is essential when it comes to maintaining your largest capital equipment investment. BTS has extensive knowledge of many common extrusion press brands, including Farrel, Sutton, Watson-Stillman, Loewy, Wean, Lombard, BLH, Youngstown, Fielding, Schloemann, and Ube. We’ve worked with presses ranging from 500T to 14,000T and dating back to the 1940s.

Our team is familiar with the design pitfalls of the older machines and can rapidly diagnose, repair, upgrade or retrofit with new technology to add years of life to your machine's life cycle.

To make sure you’re completely covered, BTS designs and manufactures a mix of highly specialized and branded components that are both integral and complementary to your presses. In addition to the extrusion press itself, we provide ancillary handling systems, as well as loading and unloading equipment.

We engineer forged and fabricated container housings for strength, reduced fatigue, and press alignment. To further improve your press’s performance, we include a quick container release system and four-point X guiding.

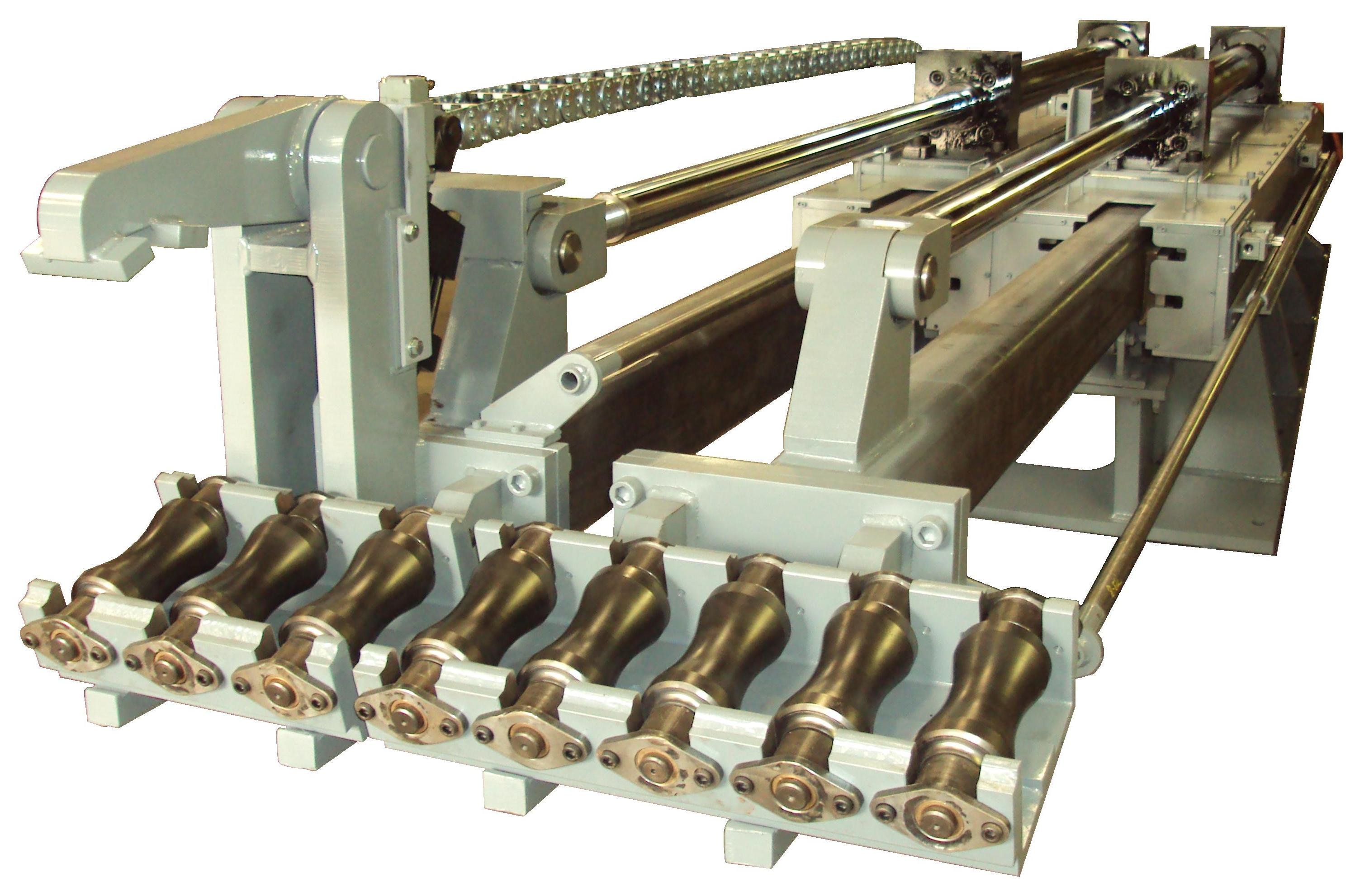

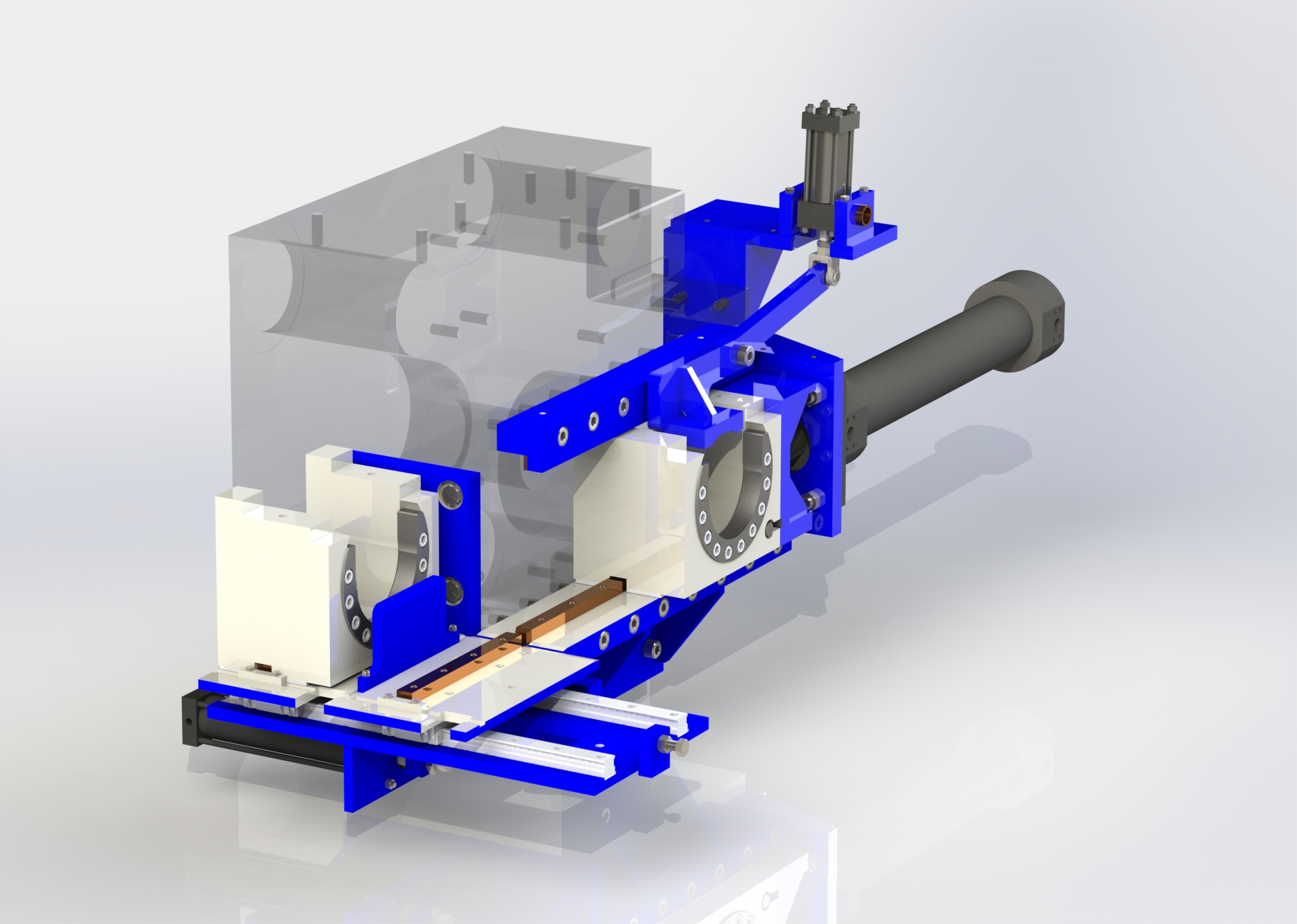

Designed with simplicity and safety in mind, our single- and dual-arm linear billet loaders include high-speed actuation by servo-drive or hydraulic power. This feature quickly and precisely delivers the billet to the extrusion press.

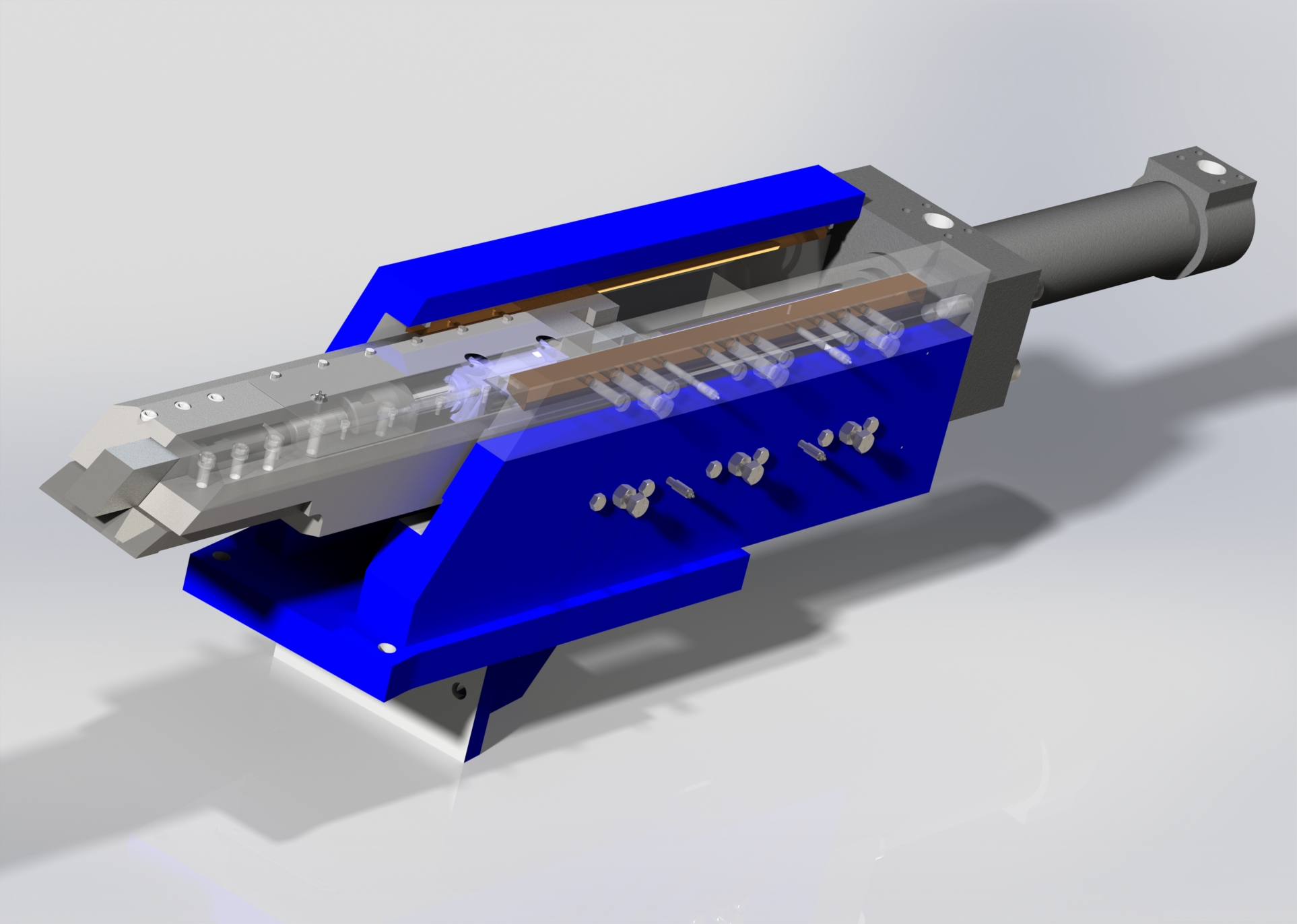

The Brilex butt shear improves shearing accuracy and comes integrated with a butt knocker system. Its four-point ram guiding system makes adjustment and alignment easy.

Does your line move frequently from shape to shape? You need to make that change as quickly as possible. Our die change system includes a shuffle table to stage dies with manual or automatic die clamping.

With BTS, you can also increase your productivity by optimizing your press frame components. We custom-engineer platens, crossheads, and tie rods to minimize maintenance and increase press life cycle.

We utilize our extrusion press technology and expertise for compaction and forging applications in steel, municipal solid waste, and other industries.

Brilex Technical Solutions not only designs and manufactures new extrusion and heavy press components, we also provide:

Looking to increase throughput and maximize efficiency, but not sure where to start?

Our engineering team can review your current processes and equipment and determine ways to improve it. If it is determined that your company could benefit from new equipment or upgrading old equipment, we offer a consultation to explore the best options for you.

Simply fill out the form , and we will be in touch with next steps.

General Manager

(330) 259-8458

Engineering Manager

330-259-8508