Shredder Boxes

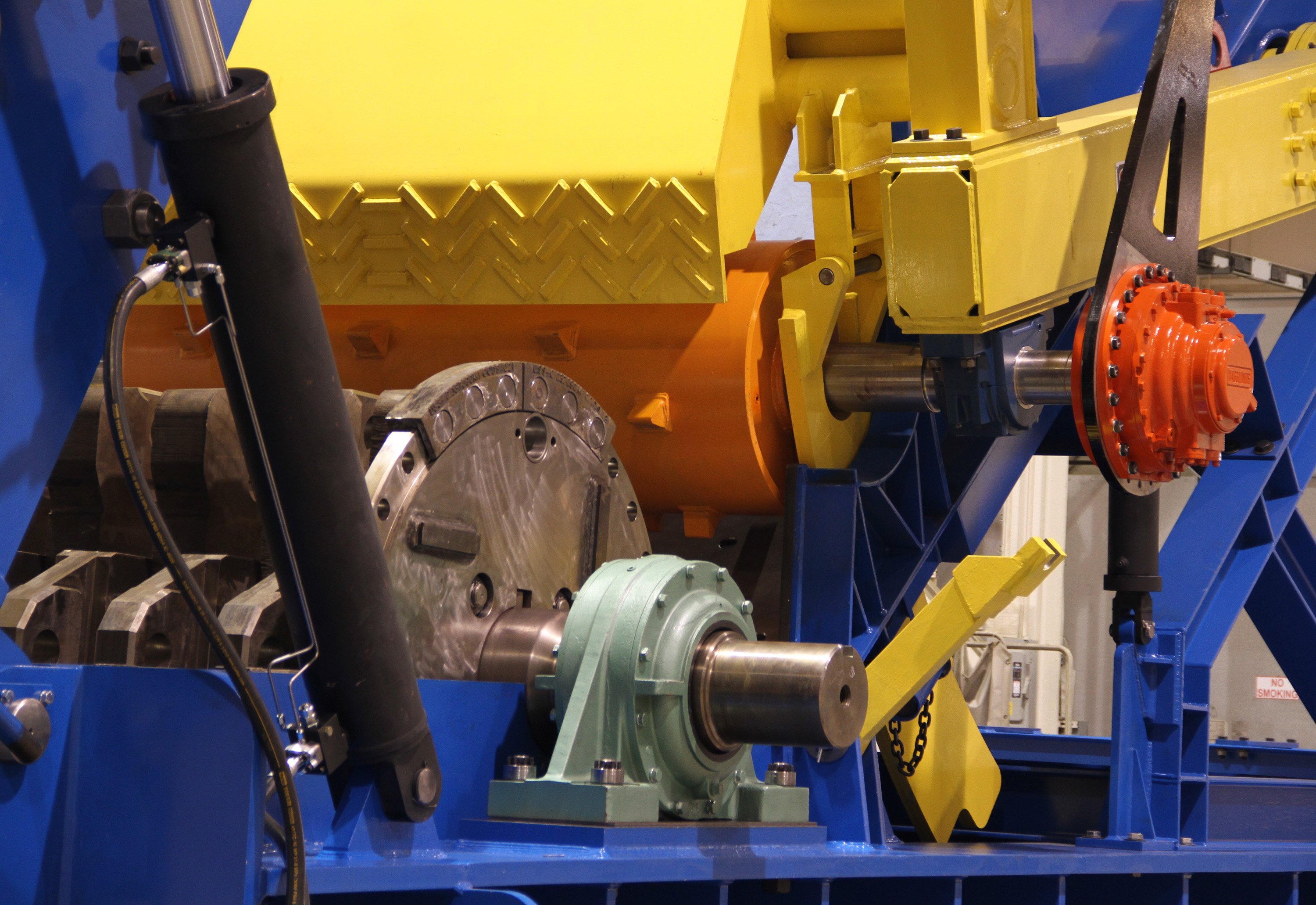

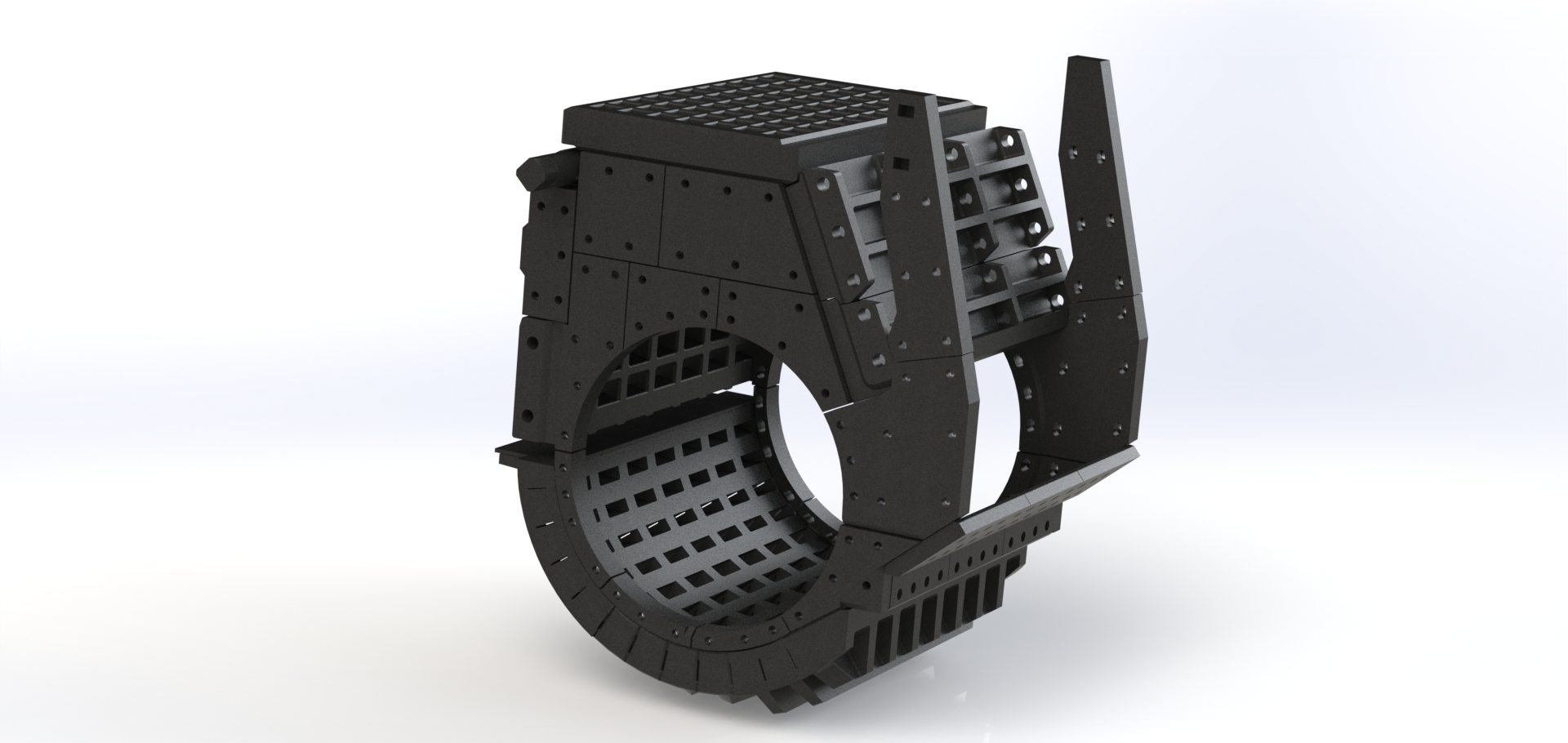

To extend the life of your equipment, Brilex Technical Solutions’ automobile shredder box is designed with minimal flexibility in the mechanical system to reduce mean time between failure.

In the market for a tough, new industrial shredder? Is your current shredder showing its age and starting to deteriorate? Does it lack the reliable design and dependability? Whatever your industrial shredder situation, Brilex Technical Solutions is here to help.

Metal shredding is a gritty, tough process that requires equipment that withstands extreme stresses. The robustness and longevity of your shredder can make or break your bottom line. We offer complete design and integration of shredder and separation systems and specialize in major component analysis for robust upgrades.

How do we make it happen? With our level of experience combined with state-of-the-art Finite Element Analysis (FEA) and 3-D design/modeling software. Each solution is tailored for your company’s specific need and with long-term quality in mind.

With a heavy-duty investment, you expect heavy-duty results. Several variables affect the life cycle of a shredder -- how well it’s maintained, what it shreds, and the number of tons it shreds per year. Our custom design engineering of shredder fleet and durable core components gives consideration to these factors and is suited for a broad array of scrap throughput demands.

Our Shredder product line is equipped with rotors up to 120” diameter, 118” wide chutes, and 9000HP of drive to process as much as 300 tons of scrap per hour. We integrate all aspects of your shredder project including:

Keeping your current shredder running reduces downtime and capital investment. That’s why Brilex is more than just a shredder systems integrator. If major components of your shredder have degraded in quality due to wear and tear, we can upgrade and replace components to keep you running efficiently at all times.

To extend the life of your equipment, Brilex Technical Solutions’ automobile shredder box is designed with minimal flexibility in the mechanical system to reduce mean time between failure.

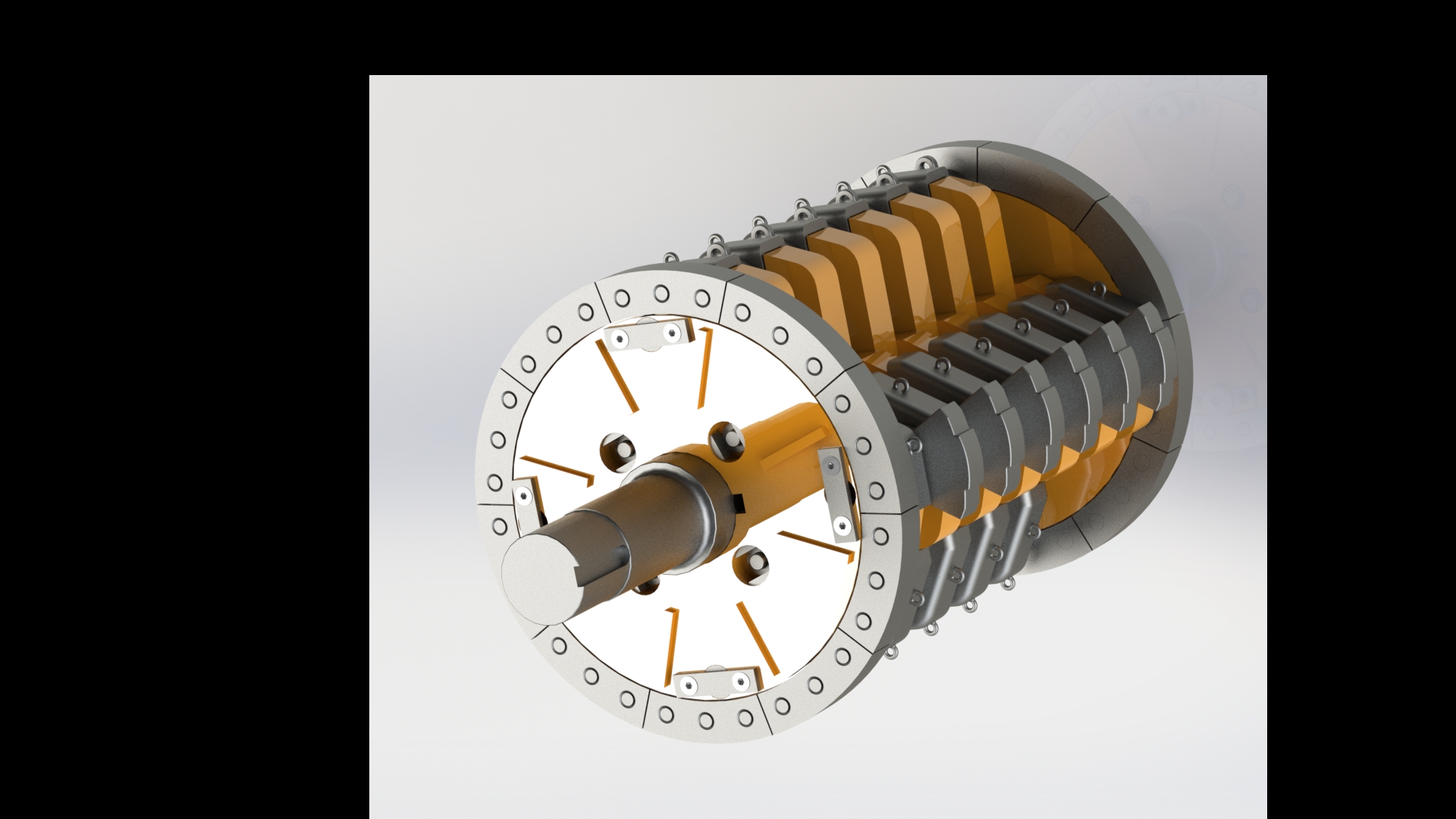

Rotor assemblies are made with the toughest steels and machined and balanced for peak performance. Rotors are sized for both efficiency and endurance and are offered as either a spider or disc model.

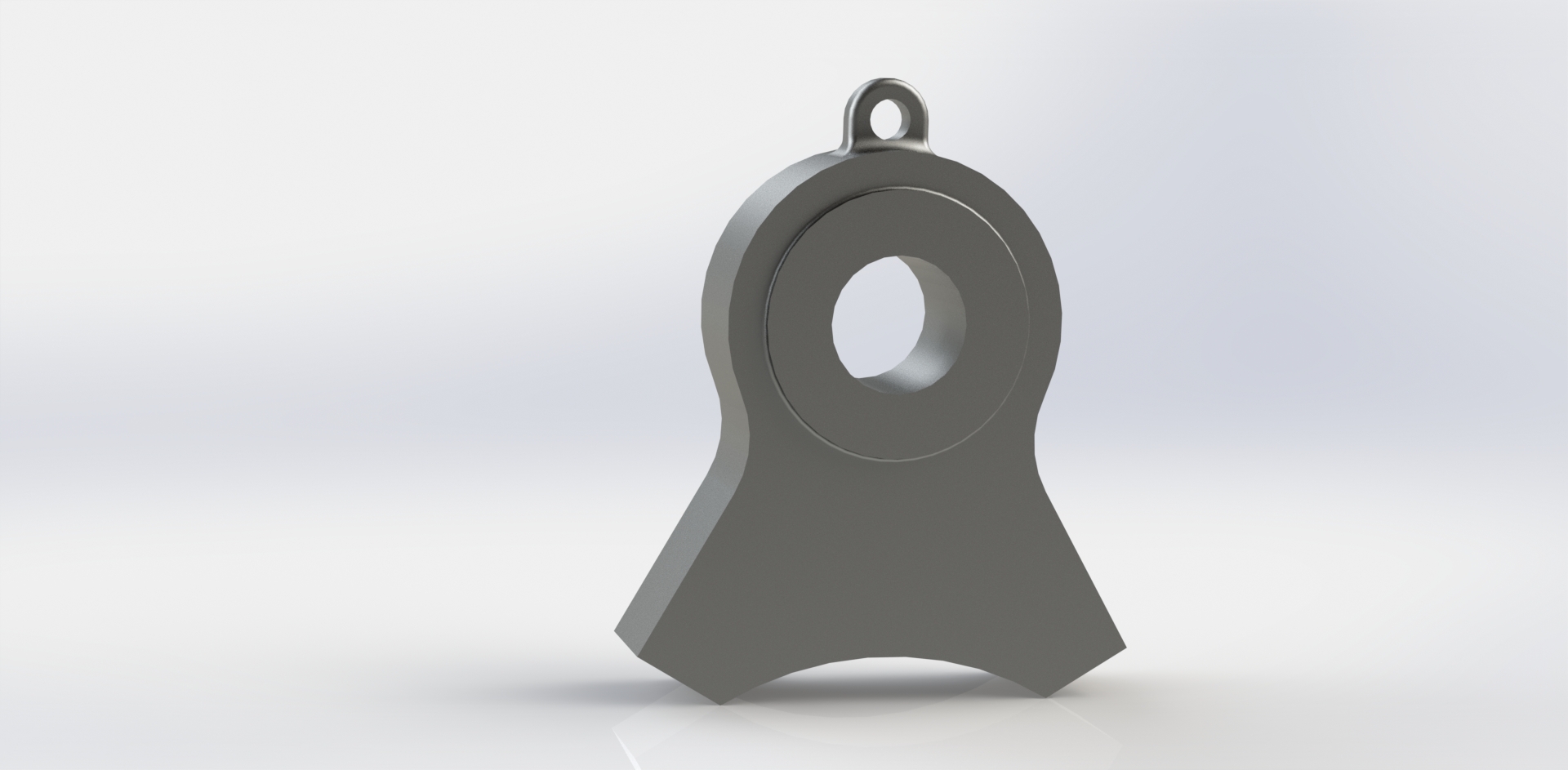

We design and build single and double feed roll models to optimize the shredding process. These components come equipped with heavy-duty rolled steel shells with integrated tooth and bar design and reinforced trunnions.

To complement our robust line of scrap shredding products, we are also your source for shears, balers, and pre-shredder design, development, and manufacturing supply.

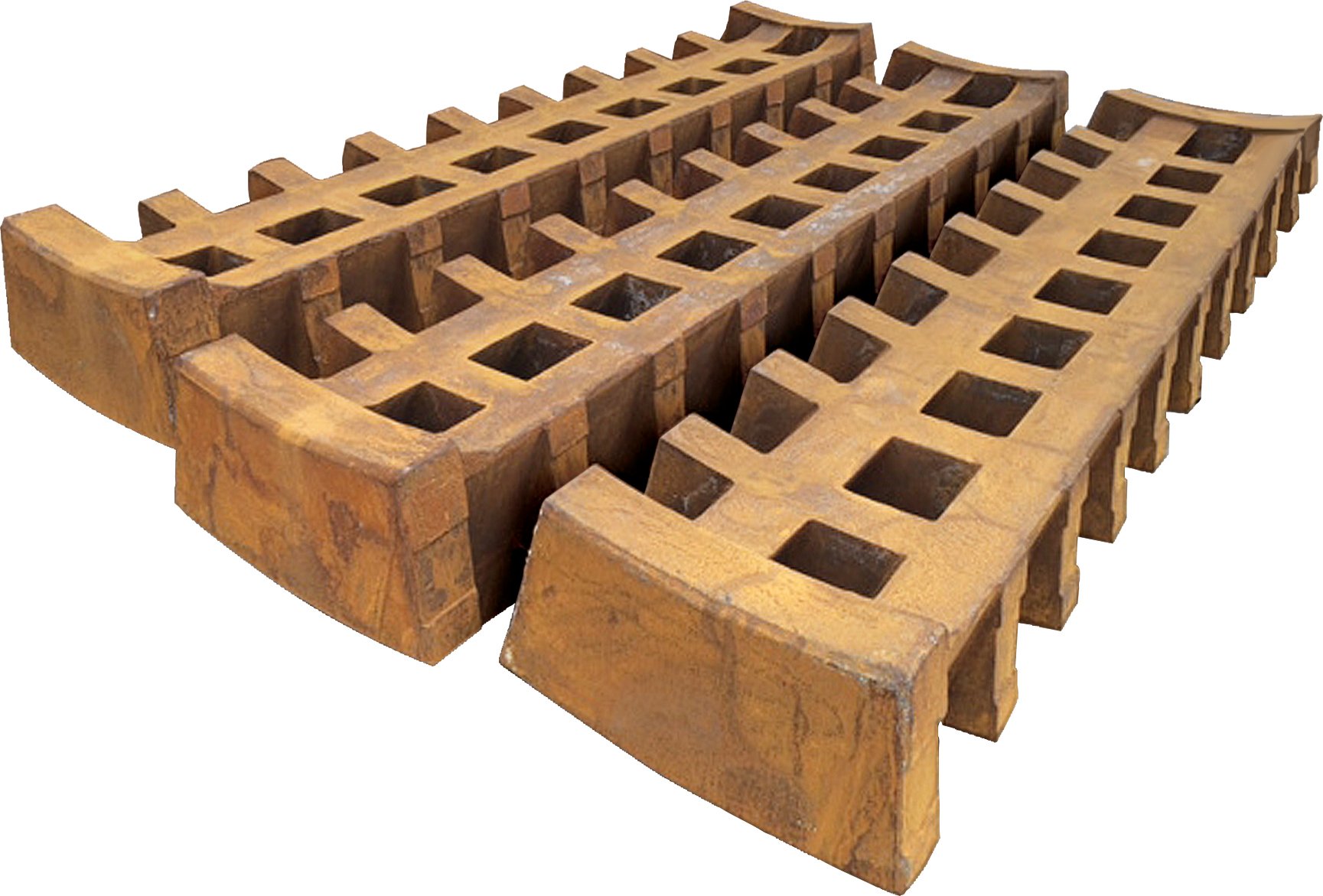

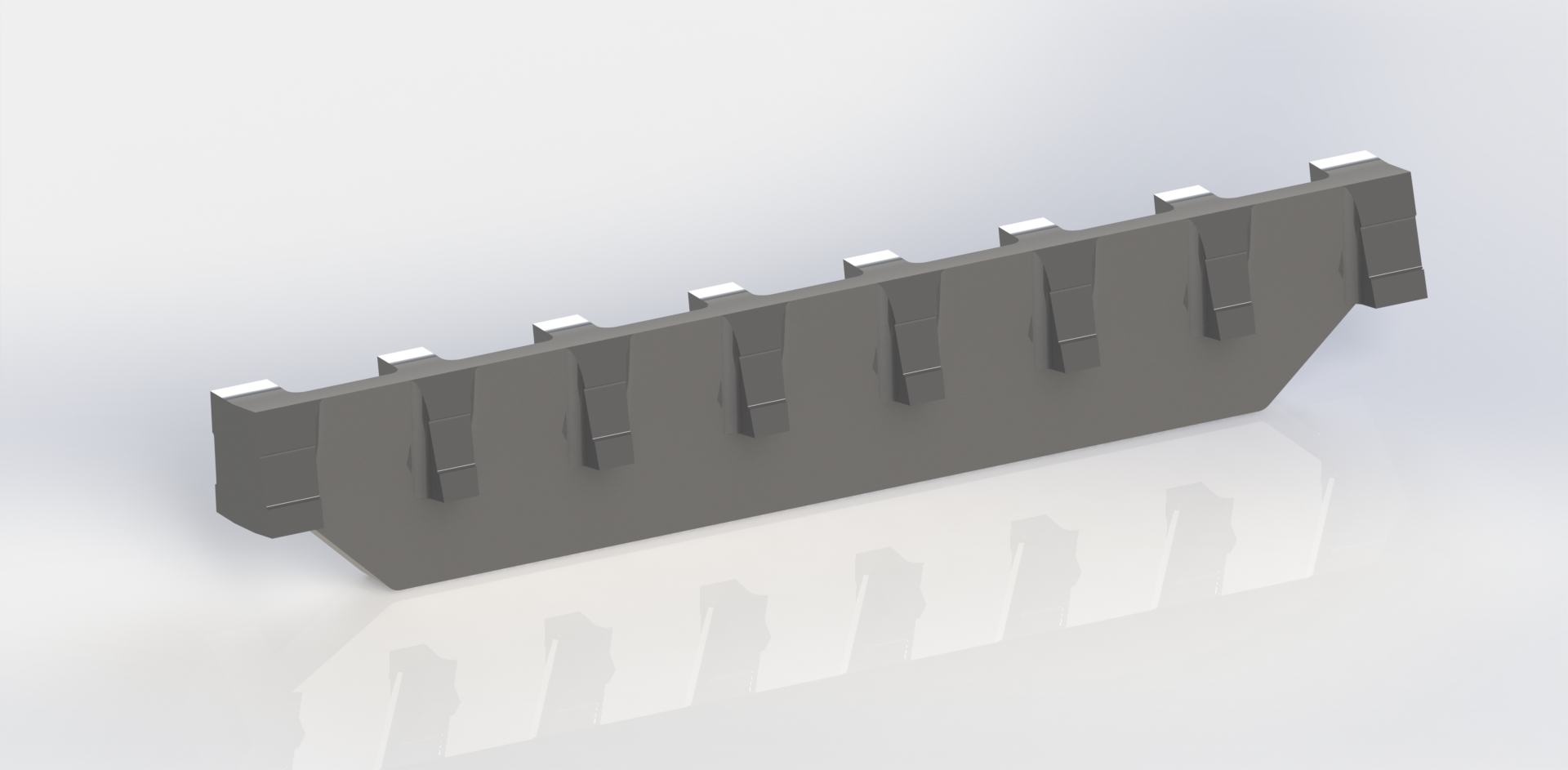

Our hammers are offered in manganese, alloy, and DHT steel and, along with pin protectors, grates, anvils, and liners, are cast to certified mechanical properties and chemistries to assure the most wearable life.

Product modeling for advanced repairs, upgrades and retrofits

For reliability in your supply chain, Brilex will stock your casting inventory for on-demand service and support. We’ve maintained a strong international relationship with our casting supplier for nearly 15 years.

If a wear component fails prematurely, we will replace it - no questions asked.

FARO Quantum Arm with blue-light Scanning Technology to identify and replace existing components and castings

We’ve designed and built industrial car shredders that are superior in the metal shredding industry. We also serve customers across markets that create synergies for us, including:

Brilex Technical Solutions maintains strong partnerships with ancillary manufacturing providers and other scrap processing solutions.

For more information on our metal shredder manufacturing services, just ask! Use the form right here:

General Manager

(330) 259-8458