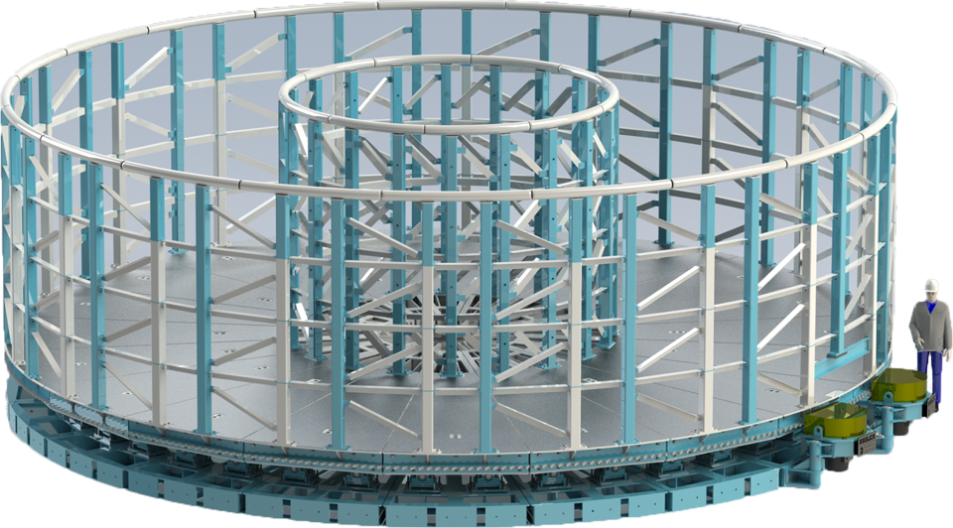

Modular Sections™ for the purpose of temporary turntable applications, simplified assembly, tear-down, and storage

PIE SECTIONS

Portable turntables arrive at a job site disassembled. The turntable is manufactured in pie sections that are bolted together on the vessel or barge. The wheel assemblies are shimmed to level the surface where the track will ride, ensuring maximum contact. The number and size of the supporting wheels is determined by the diameter and load capacity of the turntable. The design of the wheel base allows the load to be equally distributed to the deck beams of the vessel.